TGD®+ Technology: The Next Generation in Concrete Cutting

What is behind TGD®+ Technology?

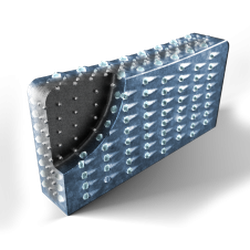

Thanks to the intelligent distribution of diamonds (TYROLIT GRAIN DISTRIBUTION), our tools already enable efficient and economical working. With TGD®+, an innovative bonding system has been added, allowing for different degrees of hardness within the diamond segment as well as smooth transitions. The result: time savings, reduced vibrations, improved cooling – all with the same long service life.

Production at the Schwaz site

To secure expertise and quality at the highest level, segments and core drill bits with TGD®+ Technology are developed and produced exclusively at the Tyrolit site in Schwaz. For this purpose, new production machinery was already installed last year.

First products on the market

The dry drill bits with TGD®+ Technology, presented at Bauma 2025, are already proving successful in practice. Wall saw blades will follow later in 2025, and parts of the wet drilling range will be upgraded in early 2026.